Exploring Cost-Effective CNC Machining for Microfluidic Prototyping

Published by Alex Hwu on Mar 18th 2025

Computer numerical control (CNC) machining is an popular method for prototyping microfluidic devices, offering precision-cut microchannels without the need for expensive cleanroom fabrication. While CNC milling has limitations in surface finish, depth accuracy, and channel fidelity compared to soft lithography or injection molding, it remains a valuable tool for rapid prototyping. With hobbyist CNC machines being an attractive option due to accessibility and low-price, some models under $200, are they suitable for microfluidics prototyping? In this post, we put a low-cost CNC machine to the test, experimenting with speeds and feeds to determine its capabilities for fabricating serpentine microchannels with widths as small as 400 microns. In total, we spent $300 on the equipment and $50 on enough supplies to machine ten to twenty microfluidic chips.

Outcome

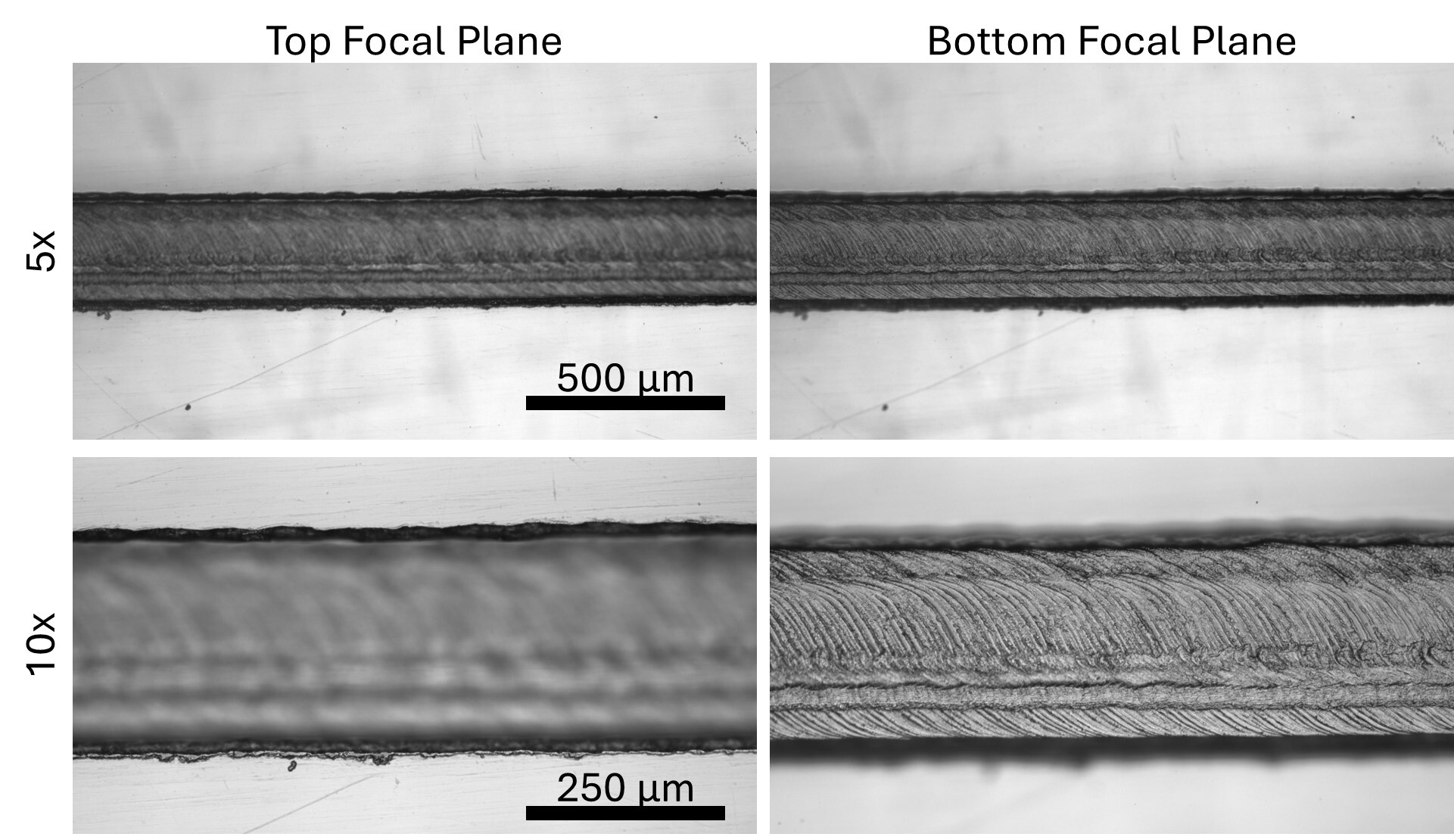

We measured the channel widths using a calibrated microscope and were thoroughly surprised by how close the channels were to 400 μm (see figure below). The channel was ~450 μm and ~360 μm at the top and bottom, respectively. We were not able to measure the depth but would expect it to be - 20 μm to + 50 μm. Continue below for the full tutorial.

Disclaimer: This is for educational purposes only and not instructional. Operating CNC without proper training and safety precautions can lead to bodily injuries.

Speeds and Feeds

Speeds and feeds refers to the cutting parameters of the tool (cutting speed and feed rate). During the CNC machining process, the spinning tool is fed across a workpiece at specific depths to cut (chip) away material. Identifying proper speeds and feeds is required for different material/tool combinations and can be an intimidating process. Non-optimal cutting parameters could lead to poorly defined cuts, workpiece burning/melting, tool breakage, and injuries. While intimidating, the best way to set speeds and feeds is to incrementally test different cutting parameters demonstrated below.

Materials Used

3018-PROVer V2

• GS-775M Motor Upgrade

• MDF Spoilboard for 3018 (1/9/25 update: not recommended because of non-uniform flatness)

• 3D-Printer Tent (Protective Shield & Cleanliness)

Computer with Fusion & Candle (Grbl Control)

Acrylic Sheet Clear Plexiglass 5” x 7” 0.04” Thick (1mm)

0.3mm Carbide End Mill

Painter’s Tape

Super Glue

Canned Compressed Air

G-Code for Serpentine Channel Design

Setting up G-Code is accessible thanks to Autodesk Fusion free license. In the video, I pattern a set serpentine channels (0.4 mm Width x 0.2 mm Depth) and go through the entire process of configuring the channels as 2D pockets for machining which includes adding my 0.3mm End Mill to my tool library. I keep my Spindle Speed at 20000 RPM, Plunge feed rate at 50 mm/min, max cut depth at 0.1 mm and vary my cutting feed rate from 100 mm/min to 300 mm/min in 50 mm/min increments to assess the cut quality for the different channels. Finally, I post-process using Grbl (installation instructions for Fusion) to obtain my G-Code for testing.

Work Piece Mounting

Securing thin plastics to the work bench can be tricky when using clamps. Uneven clamping pressure will cause the acrylic to bow in the center, resulting in poor depth uniformity. Double-sided tape is preferred but there was not a good off-the-shelf adhesive that adhered to the craft liner protecting the acrylic so I ended up using painter’s tape and super glue. Avoid machining regions of acrylic that are not lying entirely flat and set the machining surface at an area where the glue has fully wetted the craft liner on the acrylic.

Serpentine Machining

When machining acrylic, cast acrylic, which has nonuniform thickness, is preferred over extruded acrylic. Extruded acrylic has a lower melting point, making it more susceptible to gumming up the tool but we selected whatever was on Amazon to show that it is still possible to machine extruded acrylic. After mounting the work piece and loading the first file, set the zero for the z-axis and set the origin at a location where the acrylic is lying flat (setting origin and z-axis). Load and cut my G-Code files one at a time while maintaining the same origin while ensuring to re-zero the z-axis for each G-Code file to compensate for nonuniform flatness across the work piece. While machining, canned compressed air can be used to remove chips and minimize accumulation on the tool and in the channel.

Results

The image below shows full focused of the top and bottom of the microchannels (courtesy of Ehsan Shamloo). The machining marks and burrs at the edge of the channels are quite evident. We were thoroughly surprised and had expected the channels to be at least 100 μm larger than designed but ended up being 30 μm larger at the top of the channels, caused primarily by the burrs. These can be further refined to get cleaner channels when using high-quality end mills and efficient chip removal strategies.

Limitations

Depth Accuracy: While burrs will slightly increase channel widths, cut depths will be a main consideration for whether CNC is suitable for prototyping. A variety of variables can affect the final depth of the CNC’d feature. Some of the main considerations include flatness of the spoilboard, thickness uniformity of the work piece or stock material, perpendicularity of the CNC’s z-axis (tram), tool wear, and method used to zero my z-axis. When zeroing the z-axis of each G-Code file, there was a difference of 40 microns to 90 microns between the different machining areas, which could be attributed to the thickness of the paper.

Surface Finish: The CNC’d channels and chambers will have machining marks. The increased roughness also means an increased surface area, which can affect flow profiles and protein adhesion (adsorption).

Application Dependent: A CNC can be a versatile tool for prototyping microfluidics. Given the previously mentioned limitations, the budget CNC was impressively 'not bad' and can be further refined to increase the performance. It's also perfect for learning how to CNC before upgrading to a more expensive and robust machine.