KemLab’s "SQ-8" Photoresists: The SU-8 Alternative Specifically for MEMS

Published by ELEXAN Scientific on May 22nd 2025

If you're working in Microelectromechanical Systems (MEMS) and tired of the headaches that come from using SU-8, you’re not alone. Like many researchers we found ourselves stuck troubleshooting resist failures, inconsistent structures, bubbles, poor adhesion, and long bake cycles. But there’s a better way.

Enter KemLab’s SQ Series Negative Epoxy Photoresist—the plug-and-play SU-8 alternative that makes microstructure fabrication simpler, faster, and far less frustrating, we're calling "SQ-8" for short. Whether you’re building multi-layered microfluidics, tiny sensors, or other MEMS structures, KemLab’s SQ-8 gives you clean, consistent results at lower cost with less waste.

Brief History of SU-8 Name

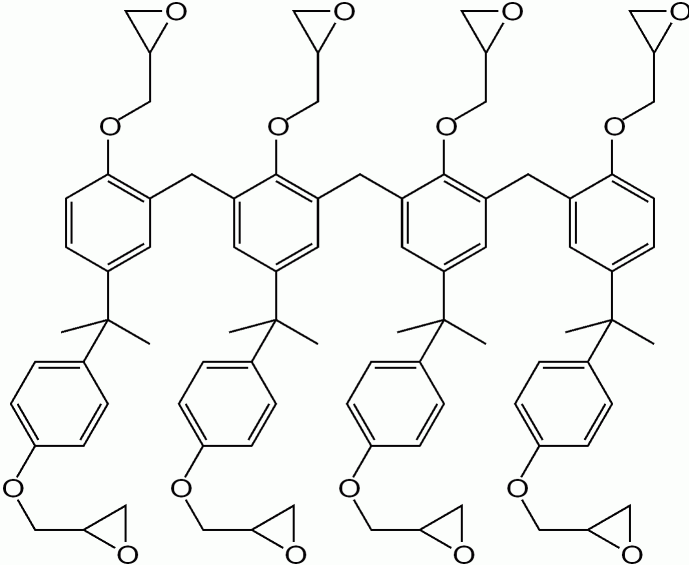

Many researchers recognize “SU-8” as the name of a widely used negative photoresist in MEMS research and fabrication. However, SU-8 originally refers to a brand name for a solid epoxy resin developed by Shell Chemical (formerly Shell Union Carbide), known today as EPON™ SU-8. This resin contains an average of eight epoxide functional groups per molecule and is used across a wide range of industrial applications.

In fact, less than 1% of the total global usage of this resin goes into photoresists — the vast majority is used in other industries for high-performance coatings, adhesives, and composites. The underlying epoxy resin’s chemical structure can be seen below in Figure 1.

Figure 1. Glycidyl ether epoxy resin with multifunctional BPA phenolic groups

Since gaining popularity in MEMS research, the term “SU-8” has been used to refer to the negative epoxy photoresist. This may have caused challenges among researchers when trying to reproduce results as there were two solvent formulations of SU-8 photoresist: Original SU-8 which uses gamma-butyrolactone and the 2000/3000 series which use cyclopentanone.

KemLab’s SQ Series Negative Epoxy Photoresist

KemLab’s SQ Series Epoxy Negative Photoresist, a.k.a. SQ-8, is formulated using an epoxy resin with the same exact chemical structure as SU-8 but sourced from an alternative manufacturer that delivers superior quality and consistency, specifically tailored for MEMS applications. The improved formulations are designed to reduce inherent photoresist oxidation or yellowing, minimize bubble formation, and easy fabrication of high-aspect resolution vertical features.

Despite the identical chemistry, KemLab does not use “SU-8” in its product name, as it is a brand name affiliated with the raw epoxy resin supplied under the brand EPON™ SU-8 so we're dubing it SQ-8. The available formulations include:

- Standard: High-quality, consistent negative photoresist for MEMS and microfluidics. Uses GBL as solvent and does not stick to oxide layers. Up to 100 μm in a single coat.

- OptiCoat: Designed specifically as a permanent protective coating for applications such as waveguides or sensors. Uses GBL as solvent and does not stick to oxide layers. Up to 100 μm in a single coat.

- MicroCoat: For thin films ranging from 50 nm to 4 μm and designed to reduce dark field loss in thin film lithography. Uses GBL as solvent and does not stick to oxide layers.

- QuickDry: Uses cyclopentanone as solvent for shorter processing times. Up to 200 μm in a single coat and sticks to oxide layers.

Is it any Good? Testing KemLab’s SQ Series Photoresist

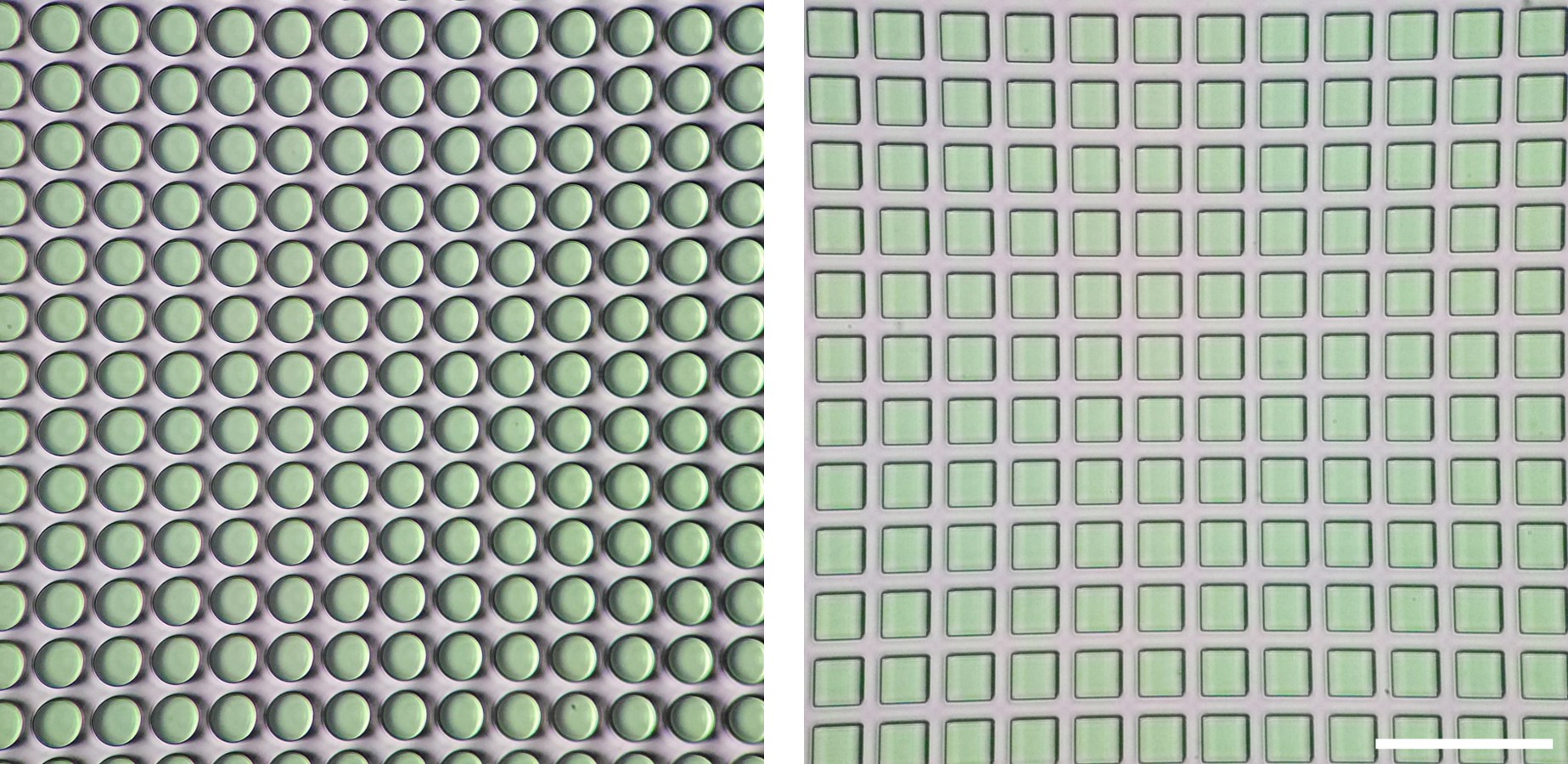

We tested KemLab’s Standard SQ, MicroCoat, and QuickDry for its plug-and-play claim as we would any new product: following the manufacturer’s data sheet. And the results? Why didn’t we use this in grad school? Everything just worked* according to the manufacturer’s recommended processing conditions, which has never happened before when using SU-8 2000. Example features made from QuickDry can be seen in Figure 2 below.

Figure 2. Optical images of circular pillars 25 μm diameter, 5 μm spacing, 90 μm thick (left) and square posts 50 μm width, 20 μm spacing, 50 μm thick (right) made with QuickDry. (Scale bar = 200 μm)

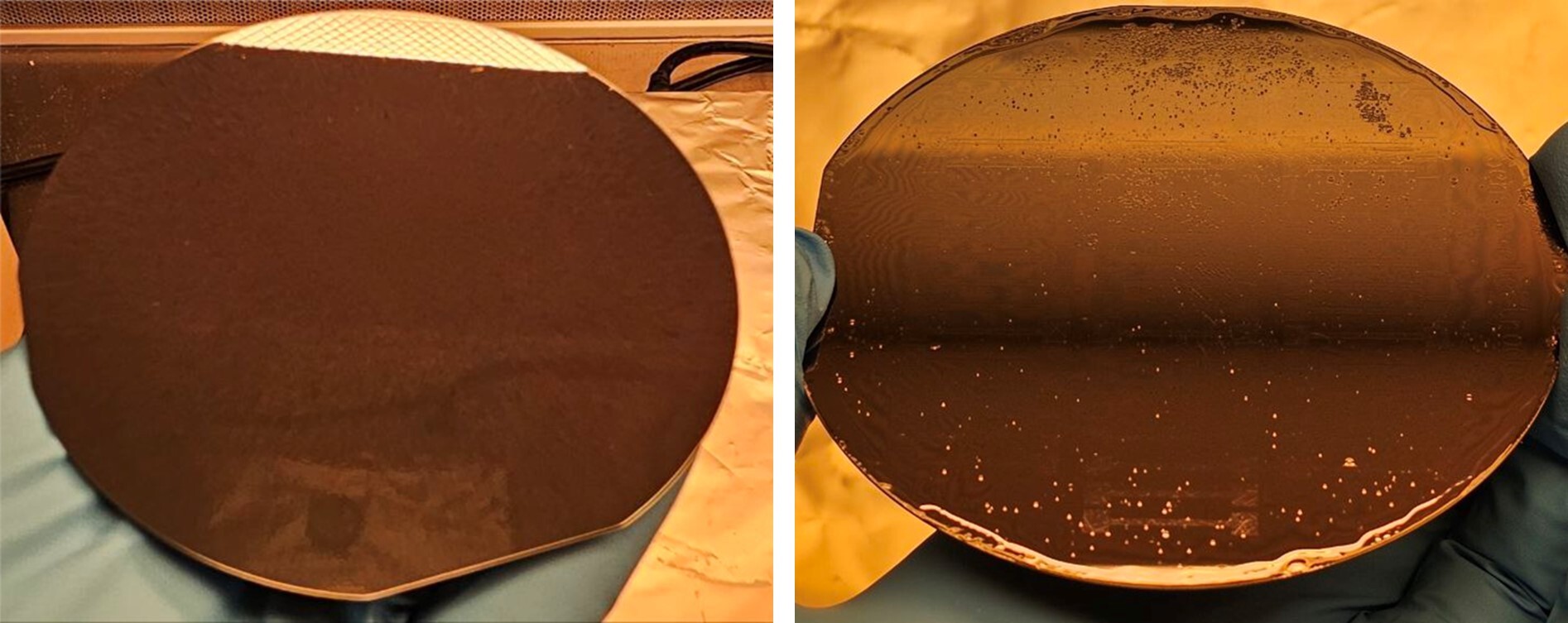

When using SU-8, it was common to troubleshoot poor adhesion, bubbles, bake conditions, and underexposed structures such as bubble formation during the softbake (Figure 3).

Figure 3. Wafer with SU-8 2000 immediately after spin coating (left) and after softbake (right).

*Some notes and prerequisites:

- Wafers clean and moisture-free.

- Only QuickDry will stick to native oxide layers. For SQ Series and substrates with oxide, adhesion promoters such as Omnicoat can be used.

- Different ambient temperature and humidity will result in different film thicknesses.

- Spin coating includes short cycle at 500 RPM for 10s (100 RPM/s ramp) followed by desired RPM for 30s (500 RPM/s ramp).

- Spin coater and hot plates calibrated and level.

- UV exposure system calibrated and level.

Concluding Remarks

KemLab’s SQ-8 Photoresist is made using an epoxy resin with a chemical structure identical to the epoxy resin used in the photoresist commonly referred to as SU-8. If we’d had known about this alternative, we would have made the switch in grad school. If you have issues with your current process or haven’t yet switched to SU-8 3000, it’s highly recommended to test out KemLab’s SQ Series Photoresists.