Description

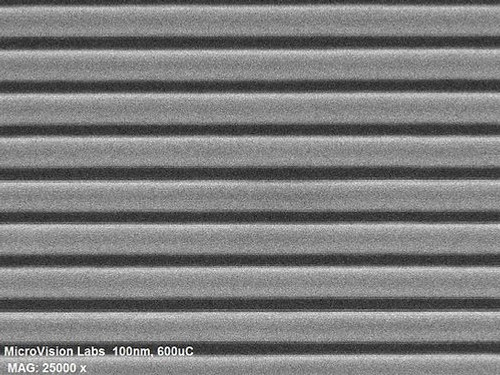

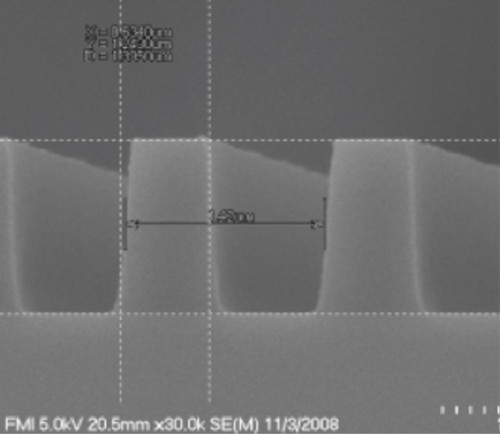

HARP™ PMMA (polymethyl methacrylate) is designed for high-resolution direct-write e-beam lithography. The HARP PMMA 500 mid-Mw formulation provides a practical balance of resolution and processing speed, enabling faster throughput relative to HARP 1000 while preserving strong adhesion to silicon, III-V, metal, and dielectric surfaces. Manufactured in anisole and developed in MIBK/IPA, HARP PMMA 500 drops into standard PMMA flows. In bilayer stacks with HARP-C™, it produces controlled undercut ideal for T-gate fabrication. Beyond patterning, it functions as a reliable protective/sacrificial coating for wafer thinning and release processes, and is also well-suited to X-ray LIGA applications. Competes directly with 495 PMMA.

Pricing valid for US, Mexico, and Canada only. Import duties applicable for shipments outside of the US.

Key features

- Tone: Positive

- Exposure: Direct-write e-beam (also suited for X-ray LIGA)

- Molecular weight: Mid-range 500,000 MW

- Throughput: Faster processing vs HARP 1000 (lower dose & quicker develop potential; process-dependent)

- Film thickness: 0.05 - 2.10 µm

- Developer: MIBK/IPA

- Solvent system: Manufactured in anisole; HARP™ PMMA products available in safe solvents (anisole, ethyl lactate)

- Adhesion: Excellent to a wide range of substrates; suitable for protective/sacrificial layers

- Bilayer compatibility: Pair with HARP-C™ for controlled undercut in T-gate stacks

- Drop-in Replacement for: 495 PMMA

| Current Resist | KemLab Replacement | Approx. KemLab FT (microns) Range |

| 495 PMMA A2 | 500 HARP eB 0.07 | 0.05 – 0.10 |

| 495 PMMA A3 | 500 HARP eB 0.15 | 0.11 – 0.20 |

| 495 PMMA A4 | 500 HARP eB 0.2 | 0.15 – 0.30 |

| 495 PMMA A5 | 500 HARP eB 0.3 | 0.25 – 0.45 |

| 495 PMMA A6 | 500 HARP eB 0.4 | 0.40 – 0.60 |

| 495 PMMA A8 | 500 HARP eB 0.7 | 0.50 – 1.00 |

| 495 PMMA A11 | 500 HARP eB 1.5 | 1.10 – 2.10 |