Description

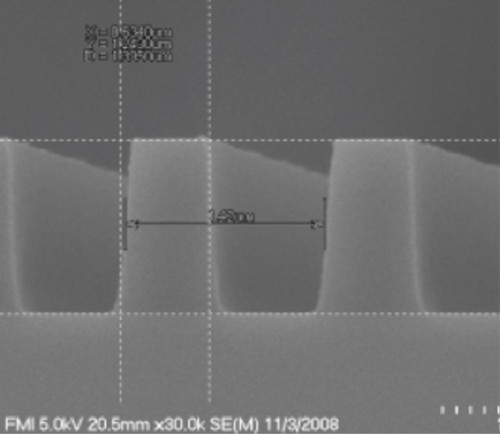

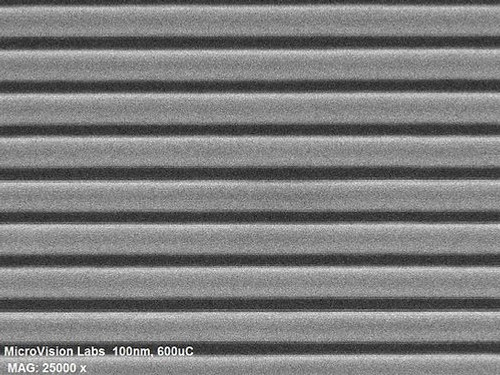

HARP-C™ is a methyl methacrylate/methacrylic acid (MMA/MAA) copolymer optimized as the underlayer in PMMA/HARP-C bilayer stacks for direct-write e-beam lithography. When combined with HARP™ PMMA (as the top resist), HARP-C provides a controllable undercut that simplifies metal lift-off and enables precise T-gate geometries. The formulation is manufactured in ethyl lactate and developed with MIBK/IPA, aligning with standard PMMA process chemistries while advancing EHS goals via safe-solvent choices. Typical use cases span III–V device research, advanced packaging, and micro-/nano-fabrication workflows, and the material serves as a drop-in alternative to MMA(8.5)MAA with straightforward integration into existing e-beam processes.

Pricing valid for US, Mexico, and Canada only. Import duties applicable for shipments outside of the US.

Key features

- Tone: Positive

- Exposure: Direct-write e-beam (also suitable for X-ray LIGA)

- Role: Bilayer underlayer with PMMA for controlled undercut (lift-off, T-gate)

- Polymer: MMA/MAA copolymer

- Developer: MIBK/IPA

- Solvent system: Manufactured in ethyl lactate; part of the HARP family of safe-solvent resists (anisole, ethyl lactate)

- Film thickness: 0.15 - 1.10 µm

- Compatibility: Designed to pair with HARP™ PMMA 500/1000 top layers

- Drop-in Replacement for: MMA(8.5)MAA

| Current Resist | KemLab Replacement | Approx. KemLab FT (microns) Range |

| 8.5 MAA EL 6 | HARP-C 0.2 | 0.15 – 0.30 |

| 8.5 MAA EL 9 | HARP-C 0.4 | 0.30 – 0.60 |

| 8.5 MAA EL 10 | HARP-C 0.5 | 0.40 – 0.75 |

| 8.5 MAA EL 11 | HARP-C 0.7 | 0.50 – 0.90 |

| 8.5 MAA EL 12 | HARP-C 0.8 | 0.60 – 1.10 |